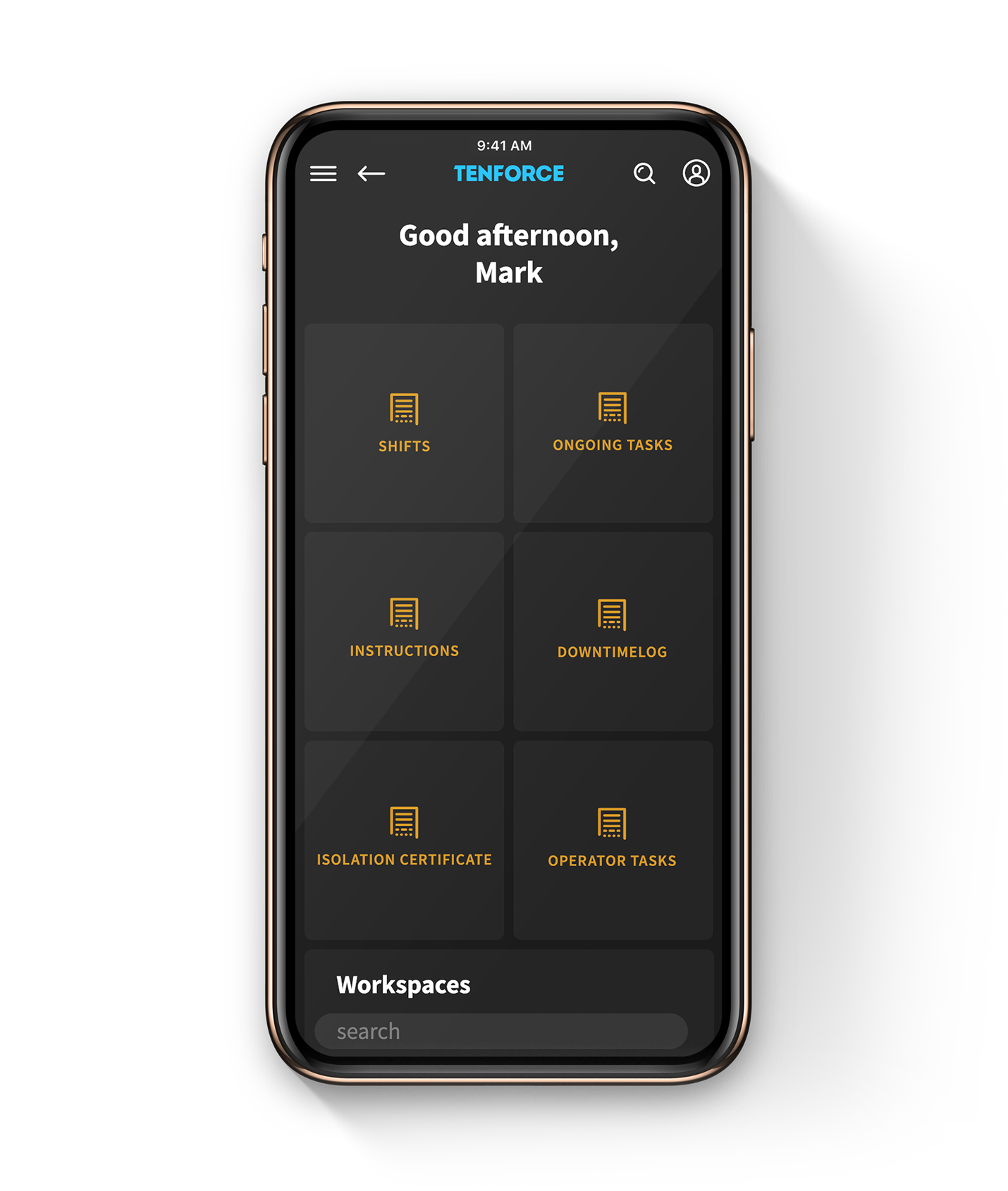

Automate Shift Management

Keep track of everything that happens during a shift with electronic logs and records

Around 60% of all incidents happen within the first 30 minutes of a shift as a result of poor or incorrect shift handover information.

Automate All Processes That are Critical to a Safe Shift Handover and Increase Operational Efficiency

Electronic Shift Logs & Handovers

- Schedule shifts and create logs per Production Line;

- Electronically document shift events, observations and roles;

- Capture asset utilization parameters;

- Automatically deliver key information to help the next shift to operate the plant safely;

- Take real-time action on instantly reported events during shifts.

Production Tasks Management

- Morning and production meetings management;

- Plan, create and automatically assign actions and production recurring tasks;

- Track actions via the workflow, due dates and sector information;

- Identify incomplete tasks and missed KPIs;

- Automated alerts.

Daily Instructions & Night Letters

- Electronically manage KPIs, actions and instructions;

- Create and plan instructions per topic & area with pre-defined start- and end-dates;

- Assign ownership by role, group or individual;

- Rule based e-mail notifications;

- Pre-filled morning or production meeting minutes, based upon events or previous shifts.

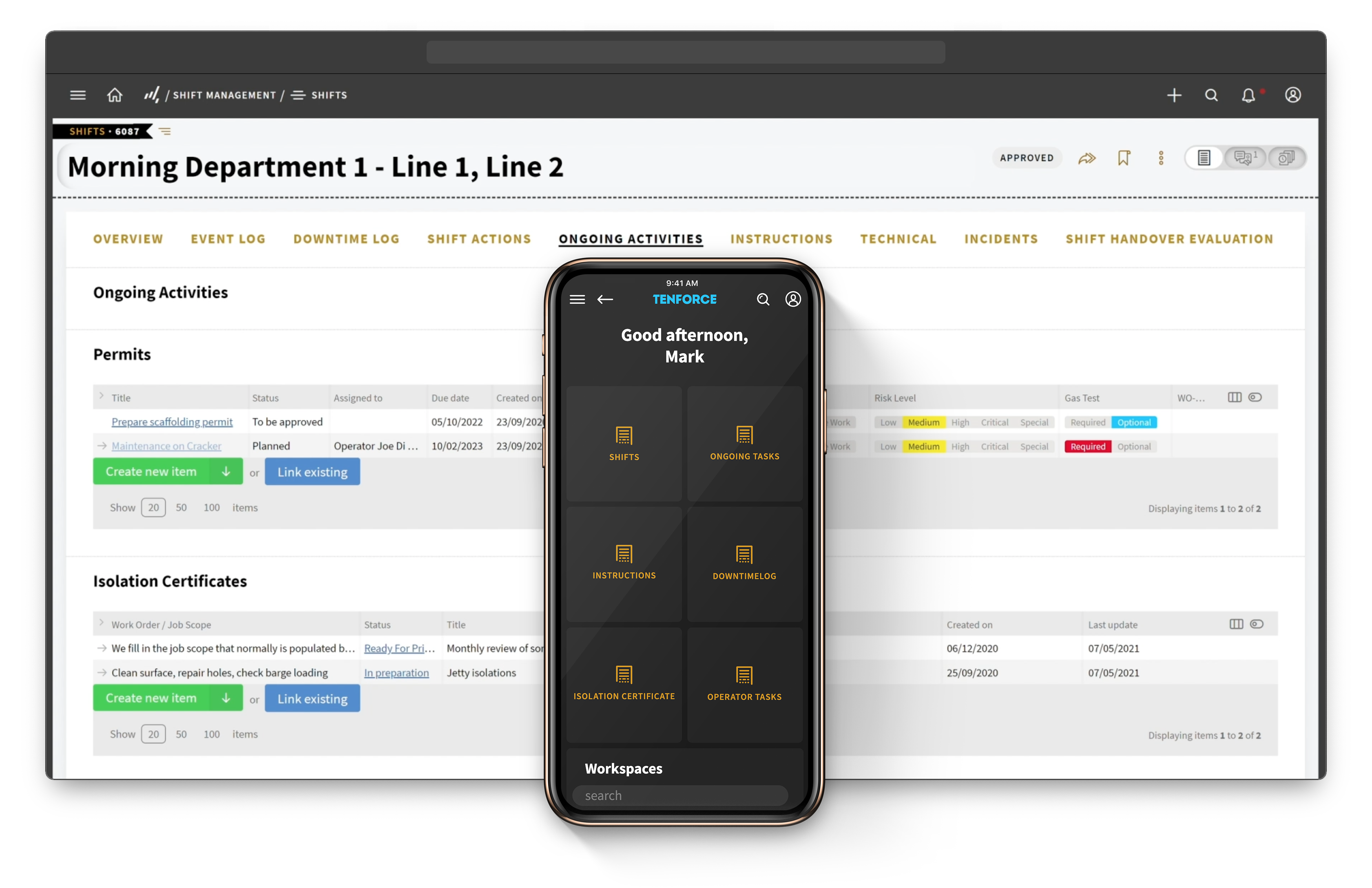

Monitor & Report

- Monitor centralized daily shift data and supervisor log with user dashboards and real time reports;

- Revise past observations equipment or process issues;

- Search according to type, dates and keywords;

- Simple real time analysis of plant performance and efficiency (OEE);

- Automate recurrent reports to management completed;

- Clean audit trail on operator instructions acknowledgement.

Enable 24/7 Shift Communication

Actions and instructions or night letters are automatically created and assigned after each production meeting. Relevant logbooks and ongoing tasks are clearly listed in role-based custom dashboards;

Move on from Pen & Paper

Storing information electronically helps operators access a historical knowledge base in order to make better, more informed decisions and keep the plant running safely and efficiently;

Boost Operational Efficiency

Critical knowledge, including open tasks, notes and other non-routine events, is collected and approved for transfer to the next shift to operate the plant safely;

Make Sure Work Gets Done

Automated action tracking ensures that all work is completed correctly and on time. Automated alerts make it easy to keep an eye on incomplete tasks that need following up.